Quality Control

At R+M Stone we take quality control very seriously. We strive to do everything to ensure that we have a satisfied customer.

From the very beginning of the process with the stone material selection until the crating and final inspection before the material

is loaded into a shipping container, R+M has procedures in place for each step of the production process to minimize any

potential issues and provide a quality product to our customer and ultimately the end user

1. Material Selection

Before any stone fabrication takes place, we choose blocks of material in the selected color range with acceptable veining.

This material selection is coordinated with the customer/client, so they are comfortable with the material that they have chosen.

If the wrong material is selected, it doesn’t matter if everything else is done right

2. Slabbing

The selected blocks of raw material are first cut into slabs in the required thicknesses. Close attention is paid to

ensure the proper veining and color range matches the approved samples.

3. Finishing

After slabbing is done, proper tools and equipment are utilized to apply the proper specified finish, prior to cutting the stone to size.

4. Detailing Process

During this step in the fabrication process, all fine detailing of the stone is handled, including slots, holes, edges, radiuses,

etc. Exact dimensions are verified for each and every piece of stone to ensure the accuracy with the design drawings.

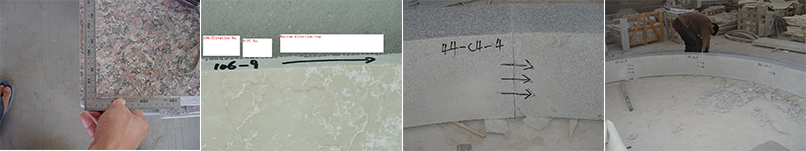

Photos are taken during each step of the production and sent to our customers, so that they are not in the dark

with where things are in the fabrication process. Not only does this documentation enlighten our customers with

the progress, but it also provides a chance to resolve any issues prior to the material being delivered to the customer.

5. Marking of the Stone

Each piece is individually marked to coincide with the shop drawings. This includes marking the direction of the

stone, which facilitates the installation of the stone, when it is received by the installer.

6. Laydown inspection

After an area of work is completed, we do a massive laydown inspection, so that any issues can be caught when all of the

pieces of stone are laid down flat in the proper sequence and pattern.

7. Crating

We pack all of the stone securely in strong crates, with proper packing material, to ensure the stone survives the long journey

from our factory to the installation site without being damaged.

8. Container Loading

One final inspection is conducted while the crates are being loaded into shipping containers. This final inspection is for damage

as well as to ensure the proper pieces are being shipped in the sequence required by our customers.